What are Purchase Order, and How to Use Them

Purchase orders are tools used by many brick and mortar businesses as well as e-commerce businesses. But what is a purchase order, what’s the process for it, and why do businesses use them?

To begin, a purchase order (PO) is a document issued by a customer to a supplier. This document contains the details of their order, such as the type of product, price, quantity, and other details.

Purchase order vs Invoice

You may be thinking to yourself, “This sounds similar to an invoice. What’s the difference between the two?” This is a frequently asked question as both purchase orders and invoices involve both a buyer and a seller arranging for payment of products or even services.

The key difference between the two is timing.

A purchase order is used at the beginning of a transaction from the client to form a legal contract between parties. Based on the details of the purchase order, a supplier will know exactly what your customer expects to be delivered.

An invoice is created at the end of the transaction by the supplier, using the details from the purchase order to request payment from the customer as agreed.

What’s In a Purchase Order?

The list below shows what should be in a purchase order:

- The Purchase Order number (to be used as a reference for the invoice; very important to track your financials).

- The customers’ contact(s)

- Payment information

- Quantity of goods/services ordered and their description

- Intended delivery address

As you can see, the details of a purchase order are rather simple and straight forward. But you may ask, is there a process for purchase orders? And the answer to that is, “Yes there is!”; but first what is the PO process used for?

What’s the PO Process Used For?

When a customer wants to buy products/services on a regular basis, they would typically issue POs. As such, though suppliers will be delivering goods prior to payment, the purchase order serves as protection from the risk of customers not paying what is due.

Besides providing legal protection, POs are used to help track payments as well as managing your inventory. It will be easier to check on ordered/shipped inventory and the inventory of products on hand.

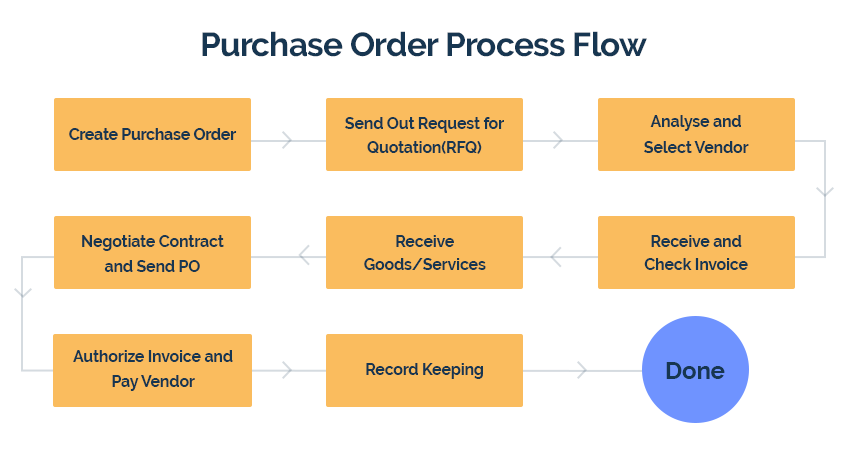

Taking these into account, below is the purchase order process for suppliers and buyers.

Supplier Purchase Order Process

- Creation of the PO: A buyer creates a purchase order and sends it to you for approval.

- Binding Contract upon Acceptance: Upon your agreement of the PO, you and your customer are legally bound for the transaction, where you are to deliver the products/services, and they are to pay you upon completion.

- Delivering the Goods: You complete the delivery as agreed, and your customer does a quality check and notifies you if there are any defects or discrepancies

- Closing the Purchase Order: If there are no defects or discrepancies, your customer is satisfied and has paid you, then the PO can be closed and documented.

This covers the suppliers’ PO process. The buyers’ PO process, however, is slightly longer and differs as well. Let’s take look.

Buyer Purchase Order Process

- Creation of the PO: The PO is created following the required approval to purchase specified goods.

- Internal Approval: Before being sent out, the PO is checked again to be verified according to the budget and documentation of the PO.

- PO Forwarded: When the PO is finalized and approved, it will be sent to the intended supplier.

- Binding Contract upon Acceptance: Like earlier, upon acceptance of the supplier, both parties are bound to the PO.

- Receiving the Goods: Upon receiving the delivered goods, the buyer checks the quality of the goods and notes down any defects.

- Documentation Matching: The PO, invoice and other necessary documents are checked for matching details.

- Closing the Purchase Order: Should there be no defect nor discrepancies, the buyer pays the supplier, and the PO is complete.

As there are times where you will be the buyer, and other times the supplier, its best to know the process both ways to avoid any confusion.

But why go through all this?

If you find yourself purchasing from suppliers often, then purchase orders are important for several reasons.

Importance of Purchase Orders

Essential Source of Information

In the long process of procurement to sales, the purchase order is the first step. The purpose of a purchase order is to bind you and the supplier. Without this first step, other documentation should not exist.

A PO also acts as a tool to help track your inventory and contains vital information you need to help you operate

Determine Size and Scope

The amount you pay and the quantity you purchase of particular products/services on POs can provide important data on setting your profit margins and how much you should sell to be profitable.

This data also provides you with information on inventory space needed, and the labor needed for your business to support or grow it.

In brief, the information you can get from a PO will inform you on how to run your operations, and whether you need to increase or decrease your efforts.

Encourages Thinking and Consideration

So by using POs, you add a sense of formality to your business, as well as professionalism. This would also make you think twice before signing off on that signature line.

Maybe you start to think, “could you find a cheaper supplier?” “Is this product worth it?”. These questions and more will come up when you need to sign off on an official agreement, as they are the thought and steps needed to move your business forward.

Consolidate Your Costs

Through the means of procurement (offline and online), you may even use purchase orders to assess your employees as well as overhead costs (everything from the cost of electrical power, the time needed, and cost of supplies) so you will be able to find out the true cost of making a product

This sort of information can provide answers to many questions on performance, such as how to increase efficiency and setting a budget.

Identify Performance Issues

So you feel your business is at a comfy level of operations. A read through of your purchase orders can provide you clues to not only your business performance but also what you can do it improve it.

By noting down your items and services ordered over time, you’ll be able to find out which of them are selling well and which ones are not as popular or underperforming.

You could even gather data on how time-sensitive or seasonal merchandise might have been affected by delays in delivery.

These are just of example data your purchase orders can give you regarding your business’ operations.

So as you can see, POs have a variety of uses and importance, not only for purchasing items but also for understanding your business. That said if you do plan to use purchase orders, its always better to do it right.

Best Practices when Using Purchase Orders

Creating Guidelines for Procurement

Whether it is written physically, or even typed digitally, having guidelines that you can refer to will help smooth out the PO process a lot.

This guideline may include general instructions to follow when dealing with POs. You can have specific instructions for your employees, such as any purchases above RM1000 should go through you or the person in charge of the financials.

Clear guidelines help your company plan and manage POs efficiently. You and your employees will be on the same page, even if they’re either sending POs or selecting sellers to buy from.

Setting Up Seller Databases

For every vendor your business has worked with, do keep records of them to help with your procurement management the next time. Even if you’re just starting out, this will start to save you time sorting through all your past vendors.

Make sure you have records of each vendor’s contact details and their payment terms. If your data is clean and easily readable, it will help you create POs much faster than you normally would. It isn’t fun to constantly look up data archives and make calls, vendor details you already had.

Restricting Expense Through your Budget

Let’s do this in 2 steps. You need to:

- Classify products/services required

- Segregate them into lists (supplies for the office, training, material to process, etc)

By classifying them like so, it will help you restrict your budget for unnecessary purchases or inefficient buys.

You may also set caps per product/service category. For example, POs for buying process materials can be capped at a certain level.

Purchase Approvals Systems

There are 2 main benefits if you use an approval system.

1. You won’t need to deal with duplicated approvals.

2. Once you’ve hired someone to manage your purchases, you won’t have to deal with delays that slow down the speed of the PO process execution.

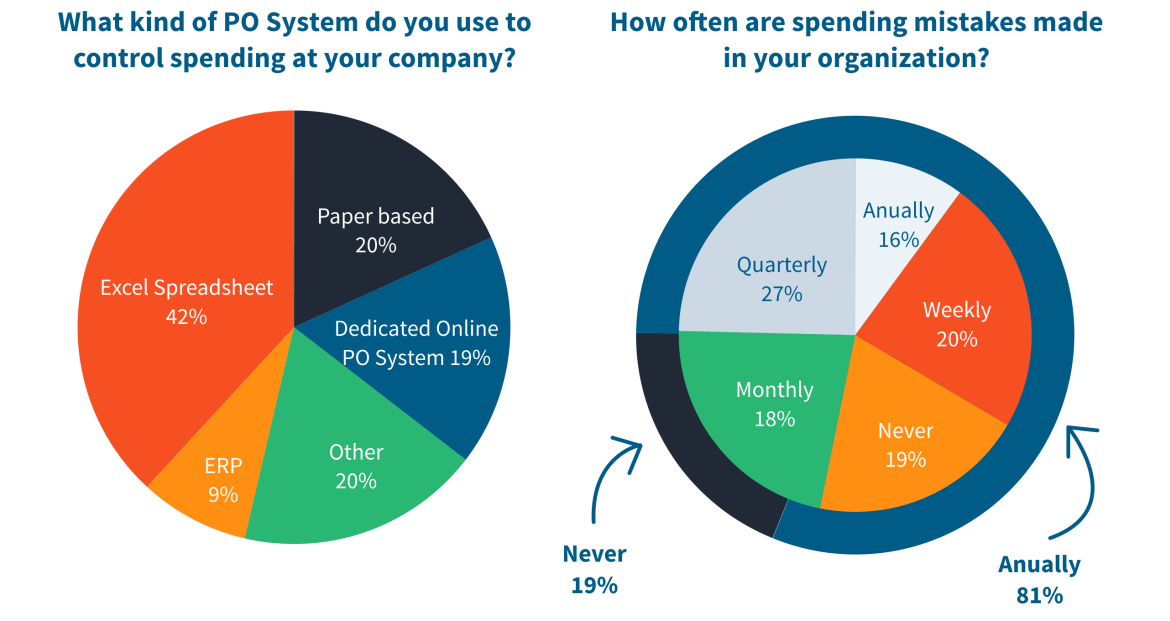

Using PO Software

An electronic PO system lets you do away with tedious processes like the old manual paperwork-based method. You won’t have to look everywhere to find an archived PO’s reference number. You also won’t need to use spreadsheets, where one wrong formula could mess up the spreadsheet.

And that’s all there is to it! For a quick recap, we covered:

- What is a Purchase Order?

- What’s the difference between a PO and an invoice?

- What’s in a PO?

- What’s PO used for?

- The PO process for a supplier and a buyer

- The importance of a PO

- The best way to utilize POs

With this information, maybe you would like to start using POs, or even improve on how you use POs right now.

(Source taken from What are Purchase Orders, and How to Use Them by DinoSync)

[/col] [/row] [row visibility=”hidden”] [col span__sm=”12″]

Want to read more? You may interest in these topics

[row_inner] [col_inner span=”6″ span__sm=”12″]

What is Reconciliation?

[/col_inner] [col_inner span=”6″ span__sm=”12″]

E-Commerce Trends and Insights

[/col_inner] [/row_inner] [/col] [/row]